We invented HPCD to replace conventional mixers. Since then it has become the industrial standards and solution to process mixing challenges. Specify HPCD to

improve and save

Please be advised: Revolmix Processing Ltd. is now: Apmixing Ltd. Please visit apmixing.com for updates.

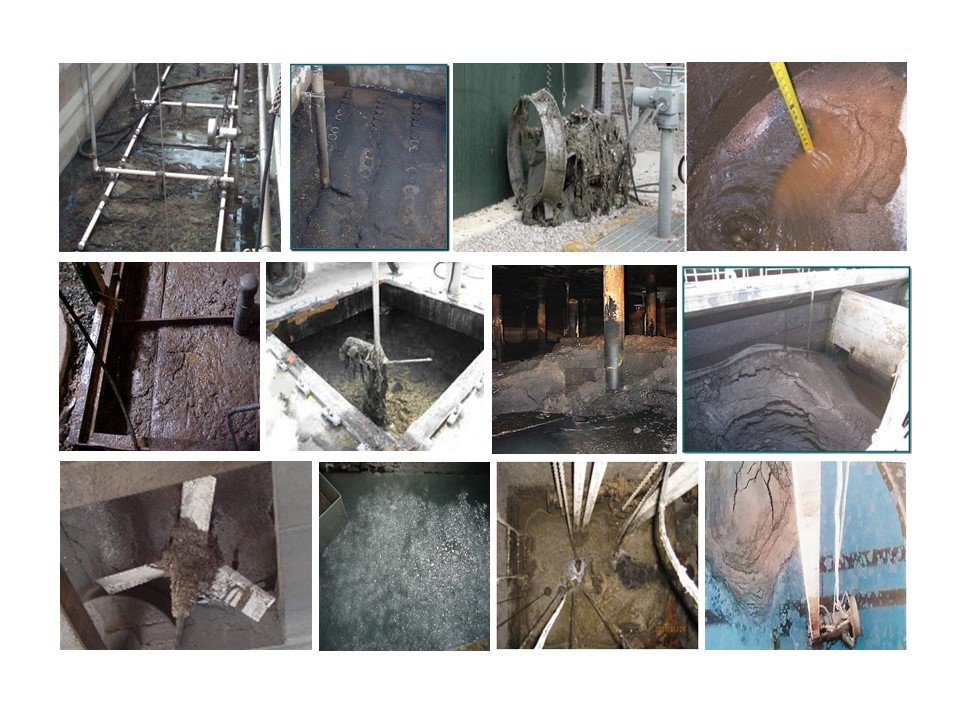

Improper mixing is costly. Boat propellers are for pushing. They caused many O&M problems when used for mixing. Advanced mixing technologies have been required for a long time.

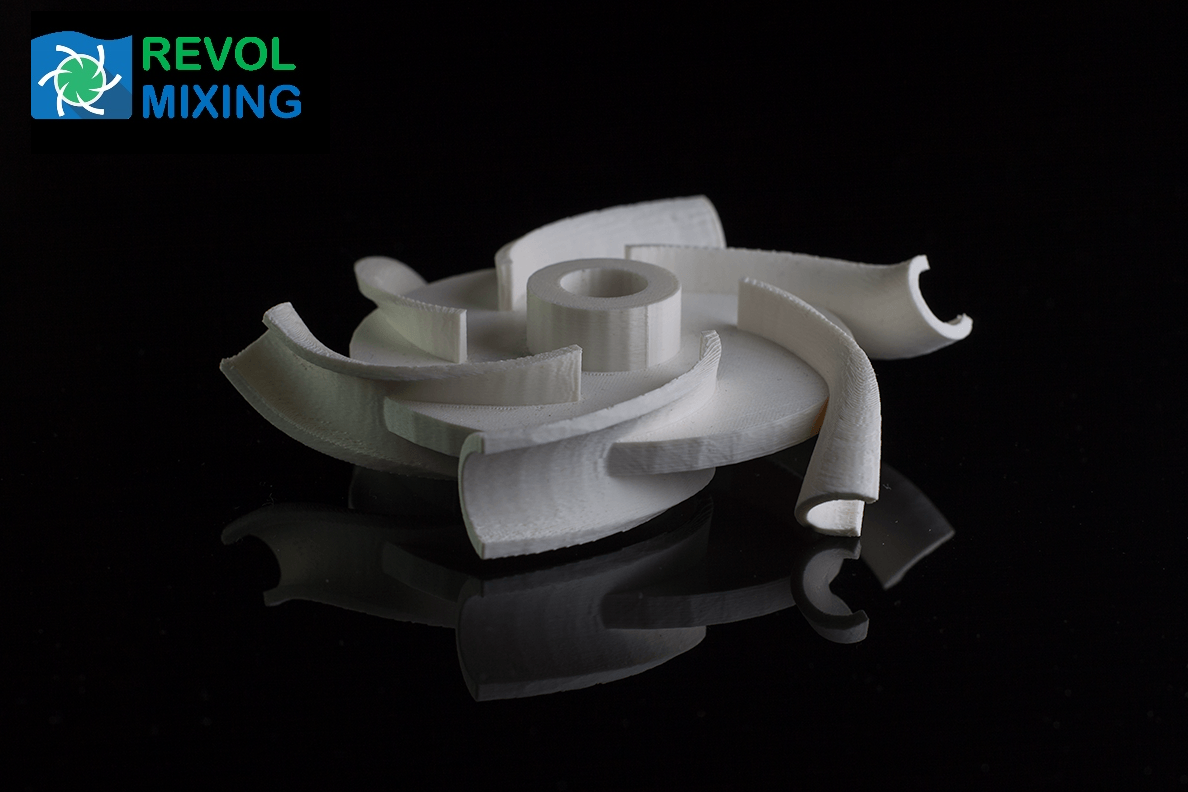

We invented HPCD to provide ideal-mixing for best process performance. HPCD disperses rather than mixes or pushes. It applies new mixing mechanism to maximize mixing efficiency with the least energy.

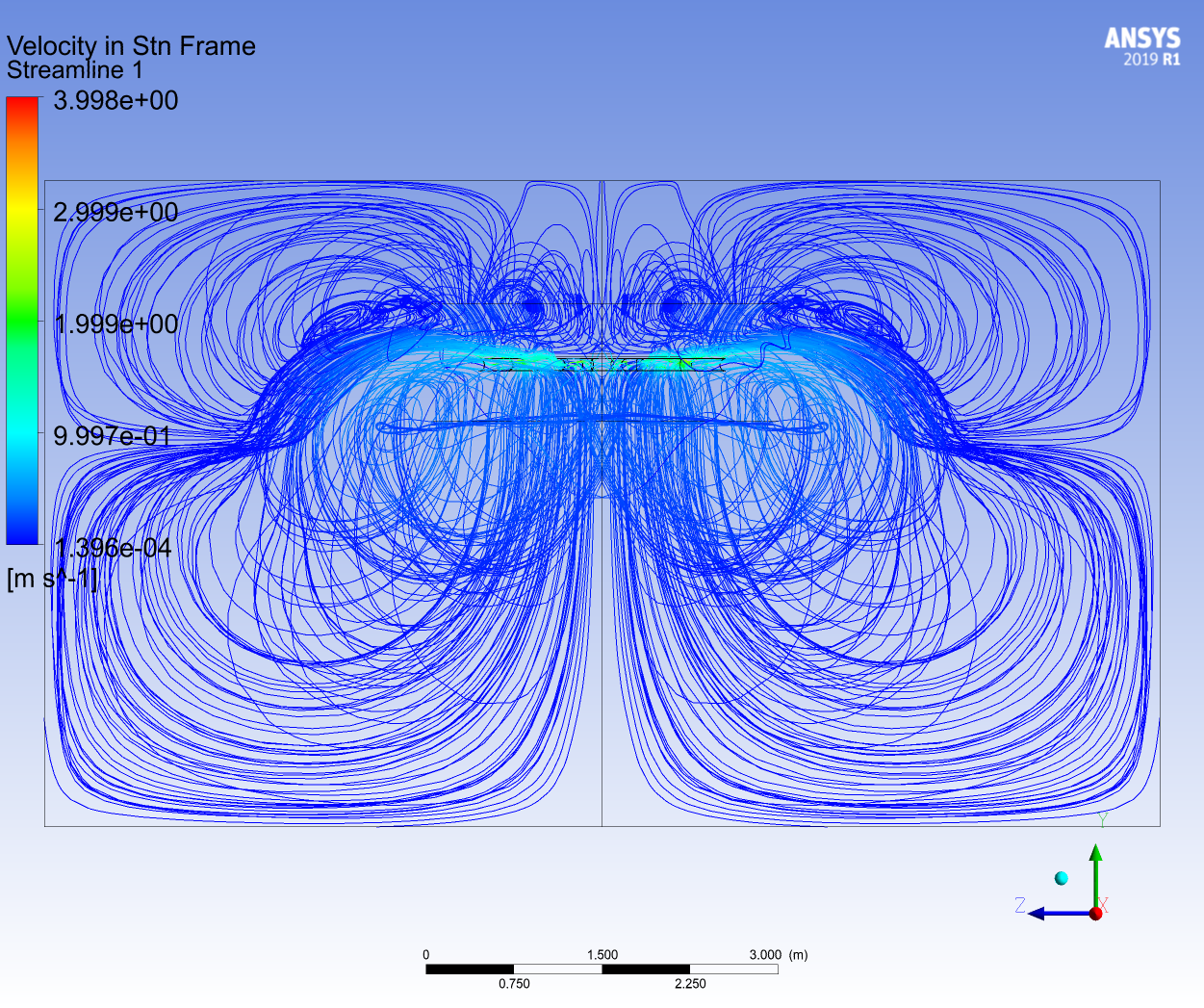

HPCD creates unique Tornado-like flow pattern with superior solids suspension capacity. It disperse particles with fireworks-like ideal mixing with the highest mixing efficiency.

HPCD is the proven solution to costly mixing problems including solids settlement, low production, difficult scale-up, etc. It is a powerful tool for process engineers to achieve the process success. It has saved our clients about 60~90% energy, over 80% maintenance costs with less than 5 years typical payback time.

You can make new tanks at least 30% smaller, or increase existing capacity by 30%.

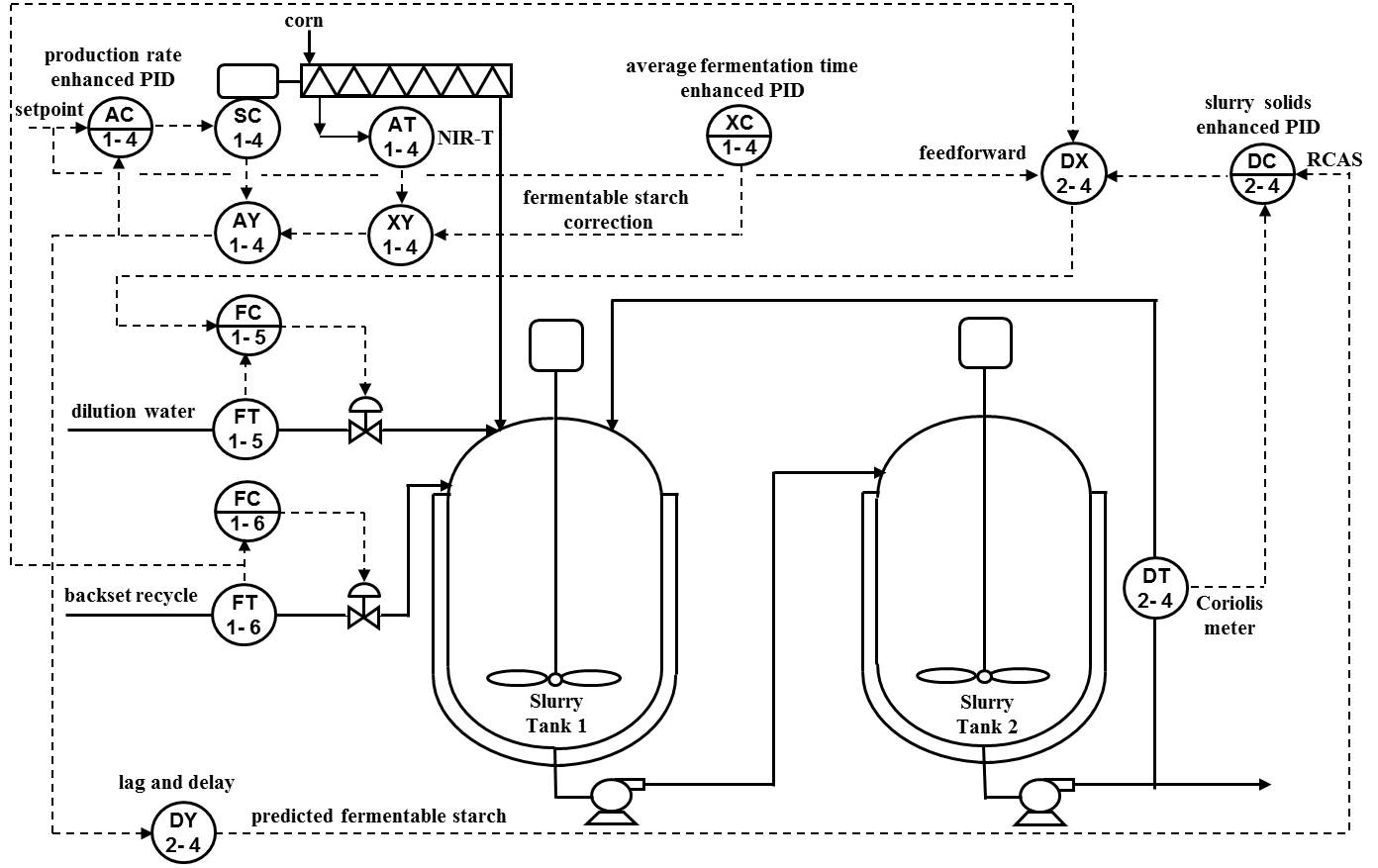

Polymer mixing requires accurate control of shear force. Too low shear has low polymer dilution efficiency while too high shear will damage the long polymer chain.

Both applications require precise control of the G value – velocity gradient. HPCD has 2 or 3 times impeller vanes providing about 150% higher pumping rate than other products. It improve the performance and save chemical costs.

Chemical mixing has challenges such as super fast mixing, tall reactor, changing liquid properties, combined with other mixing requirements. HPCD could create the engineer desired flow patterns to optimize your process performance

Conventional mixers push solids down. HPCD lift solids up with tornado-like power

Chemical mixing

Varies processes have different mixing requirements. Please call us to discuss your specific requirement.

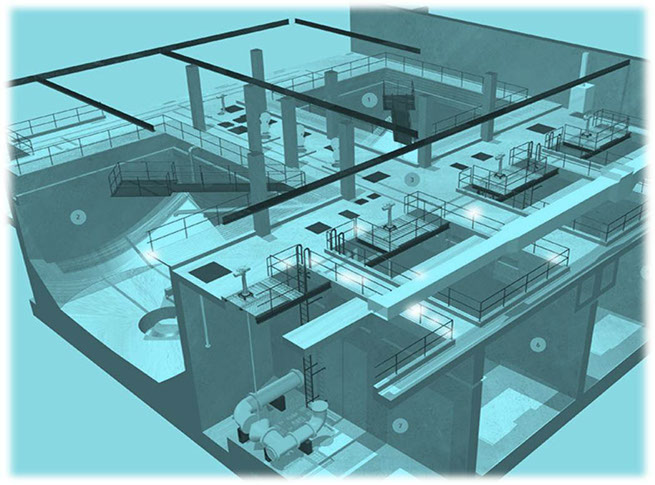

We are able to design, fabrication, install and commission the mixing system to the satisfactory of your process performance.

Unlike other manufacturers that guarantee equipment operation, Revolmix Guarantee the performance of your process units

BanffCaseStudy on ESE Mag

ESE-CaseStudy

I’d like to congratulate ourselves: one of my mixer patents granted. The invention is the Next Generation mixer of traditional...

“Yes, the power withdraw of your mixer is about 1.25 HP!”, the operator confirmed after he took the readings from...

How much energy is wasted in mixing with baffles installed? Traditional mixing products, such as Pitched-blade turbines, propellers and their...

We always remember and appreciate the financial support from AITF during our product development stage. It was a great help...

https://aiche.confex.com/aiche/2013/webprogram/Paper308085.html

Our impeller was designed with no impact by harsh environment including large amount of fibrous debris. It is ragging -free....

Solids settlement at Banff WWTP Complete Mixing Tank (CMT), once was 5 feet high along the tank wall. It causes...

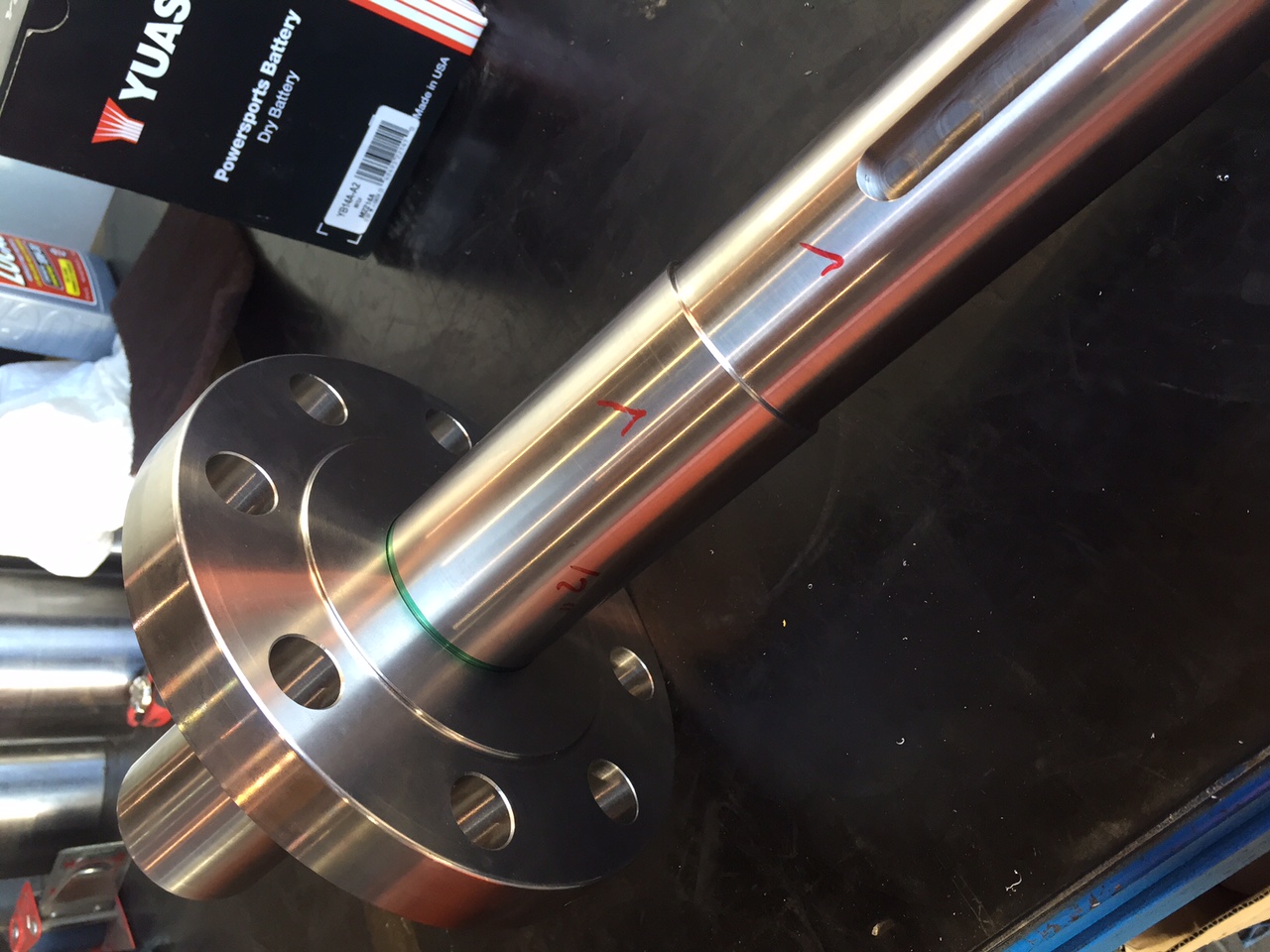

Engineered for Best Performance

Optimize Operation

What’s Mixing Problems do you have

test 3

sfd Most of current mixing technologies have been developed for more than half a century. They’ve been studied widely and...

Begin The Journey to a Better Fulfilling Life

Food and Beverage

Mining

Wastewater Treatment

Oil/Gas/Refinery

Pulp and Paper

Water Treatment

Revolmix

To improve and save

KINKERS

Collaboratively administrate empowered markets via plug-and-play networks. Dynamically procrastinate B2C users after installed base benefits.

Recent Comments