Technology

All reactions, physical, chemical, physical-chemical and biological, require contact among reactants or media. Mixing is the physical measurement to assist such contact for rapid reaction. Mixing technology applied plays a critical role to the process success .

Cost of problematic mixing is too high

For a long time, the industry has experienced various challenges including insufficient mixing, enormous energy input, difficult scale-up, etc. with price of billions dollars losses annually. Conventional technologies have limited potential for further improvement. To achieve satisfactory performance, more complicated systems are employed: add baffles to the reactors, install multiple impellers or significantly larger mixers. All end up with compromise of energy and cost.

Sustainable development calls for new technology

Energy efficient processes and equipment have been studied and developed in many industries. Mixers developed half a century ago are still widely used.

RevolMix’s understanding of mixing

The ultimate goal of mixing is homogenization which has three levels:

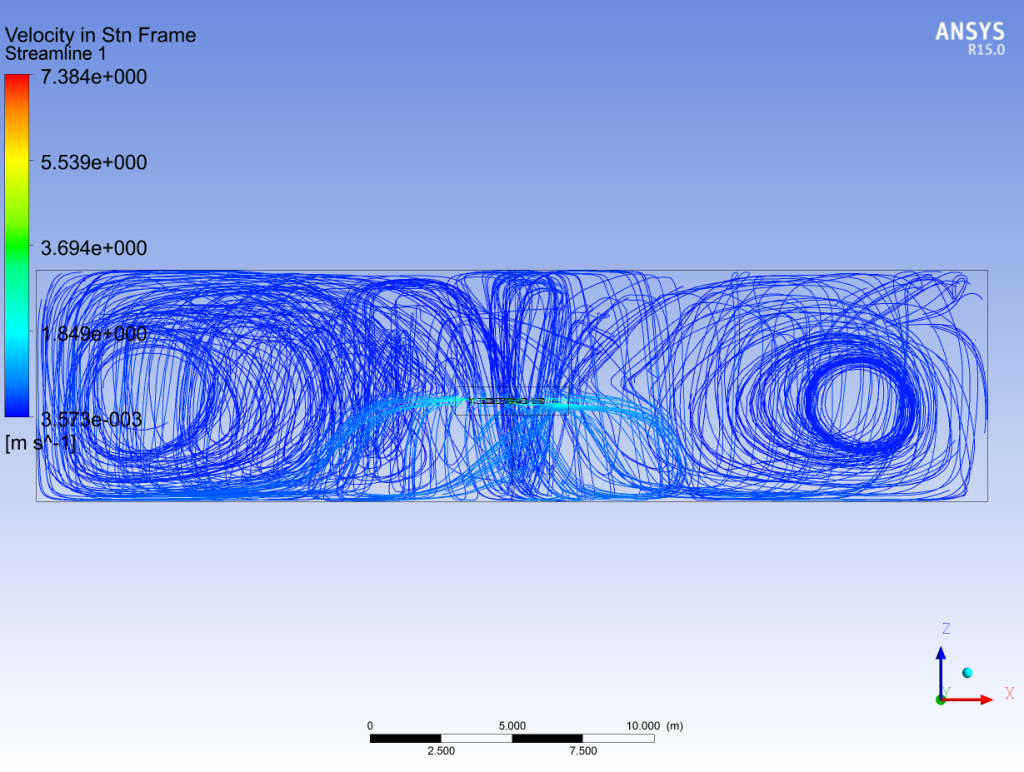

- Conventional Level: macro scale, creates water movement of large flume in the reactor and has limited “mixing effect”. Only velocity changes in the direction and value between the neighbor smallest particles will result in mixing. Flow pattern like a school of fish does not mix. Current studies and products are focus on the macro-scale level.

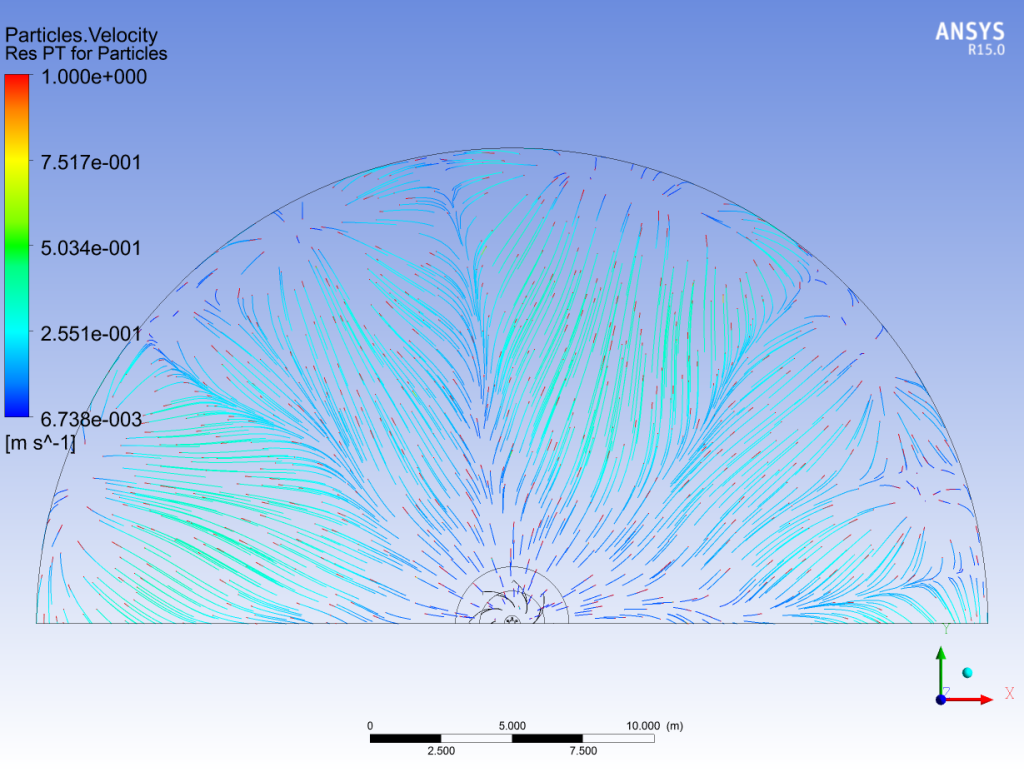

- Dispersion Level: in the mid of macro and micro scale, focus on breaking the media to the smallest volume and distributing to various directions. With the breakdown of media volume, the frequency of reactant contact is exponentially increased, so is the reaction dynamic rate.

- Diffusion level: micro –scale, if talked about molecular level or Brown movement , it is temperature dependent.

Impeller Design Variables to be optimized to best suit your applications:

D-Diameter of Impeller.

d-Diameter of plate

N-Number of vanes

W-Width of vanes

α-Vane dist end angle

β-Vane proximal end angle.

n1-number of vane above plate

n2-number of vane below plate

n3-number of vanes bisect plate

L-length of vanes

Sustainability is our common goal. Energy saving is not only an issue of cost saving but also our responsibility for future better living. In Revolmixing, our focus is always on the both performance efficiency and energy efficiency.

For a long time, the industry has experienced various challenges including insufficient mixing, enormous energy input, difficult scale-up, etc. Conventional technologies have limited potential for further improvement. To achieve satisfactory performance, more complicated systems are employed: add baffles to the reactors, install multiple impellers or significantly larger motors. All end up with compromise of energy.